Receptor microdinámico para auriculares y audífonos Bluetooth

El RE-0633RS-001 es un receptor microdinámico de alto rendimiento diseñado para ofrecer una salida de audio clara y fiable. Con un diseño compacto y conforme a RoHS, este receptor es ideal para diversas aplicaciones de audio. Incorpora una bobina móvil de cobre, un imán de Nd-Fe-B y un armazón de ABS duradero, lo que garantiza una excelente calidad de sonido y un rendimiento duradero.

Para fabricantes de dispositivos de comunicación

Venta al por mayor y OEM/ODM | 📧 Póngase en contacto con nosotros

🧪 Muestra

Modelo estándar gratuito

Se aplican gastos de envío.

🧭 Orden de juicio

A partir de 200 unidades

Prueba antes de realizar el pedido completo

📦 MOQ

3000 unidades

Pedido mínimo completo

- Modelo: ECM-RE0633RS-001

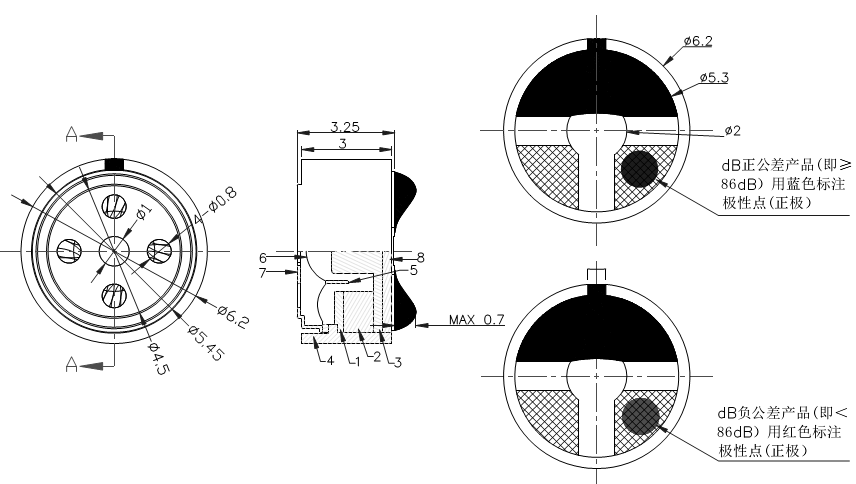

- Dimensiones: 6.2 × 3.25 milímetros

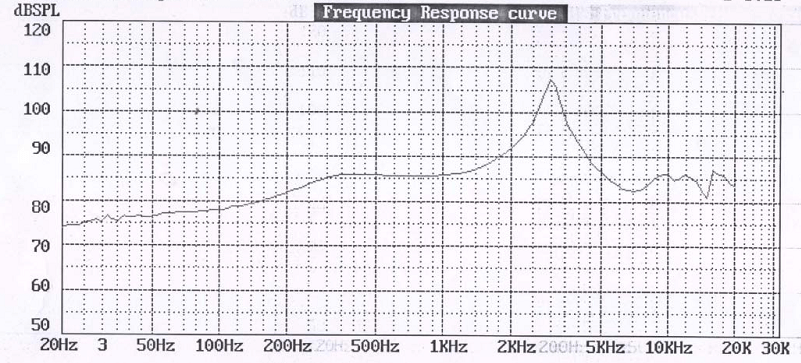

- Sensibilidad: 86 dB SPL ± 3 dB

- Impedancia: 30 Ω ± 20%

- Poder: 1 mW

- Respuesta frecuente: 20 Hz ~ 20 kHz

¿Es esto cierto y tiene algún efecto en los oídos que ya utilizan audífonos?

Hola Noel,

Gracias por su pregunta.

Aunque este receptor no está específicamente certificado o diseñado para audífonos, se ha utilizado en aplicaciones de audio similares. Le invitamos a probarlo en su proyecto, especialmente si su dispositivo permite cierta flexibilidad en las especificaciones del receptor.

Tenga en cuenta que, para su uso en productos sanitarios regulados, pueden ser necesarias pruebas adicionales de validación y compatibilidad.

Comuníquenos los requisitos de su proyecto o sus objetivos de rendimiento y estaremos encantados de ayudarle.