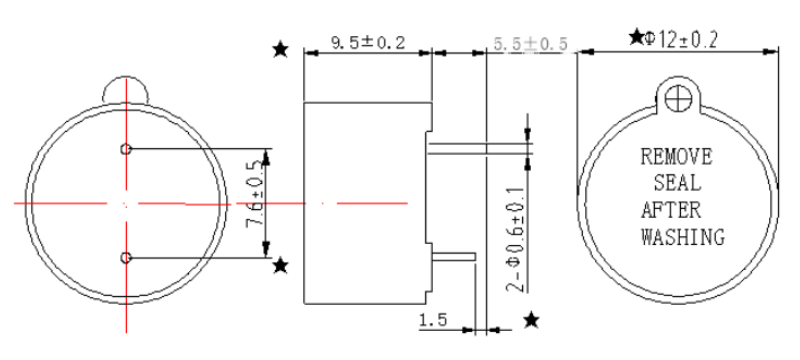

This compact Φ12.0×9.5mm electromagnetic active buzzer (Model: ECM-12095BZ-5V2500HZ) is designed for high-volume OEM integration. Operating on 5V DC, it features a built-in oscillation circuit that produces a fixed 2500Hz alert tone the moment power is applied.

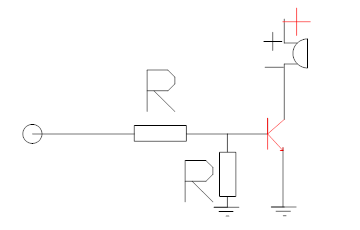

Its simple “power-on, sound-on” operation eliminates the need for external drivers, making it a reliable and cost-effective choice for industrial controls, home appliances, computer motherboards, and electronic devices requiring a straightforward audible signal.

Internal Design: Combines a coil, magnet, and an integrated oscillator circuit. When DC voltage is applied, the oscillator drives the coil, causing a diaphragm to vibrate at the set frequency.

Key Advantage: Compared to passive buzzers, this active type simplifies your design—no microcontroller PWM or external timer is needed. Just switch the DC power to control the sound.

Compact footprint (Φ12.0×9.5mm) with standard pin configuration for easy through-hole PCB mounting. The diagram includes recommended PCB keep-out area for optimal sound projection and assembly clearance.

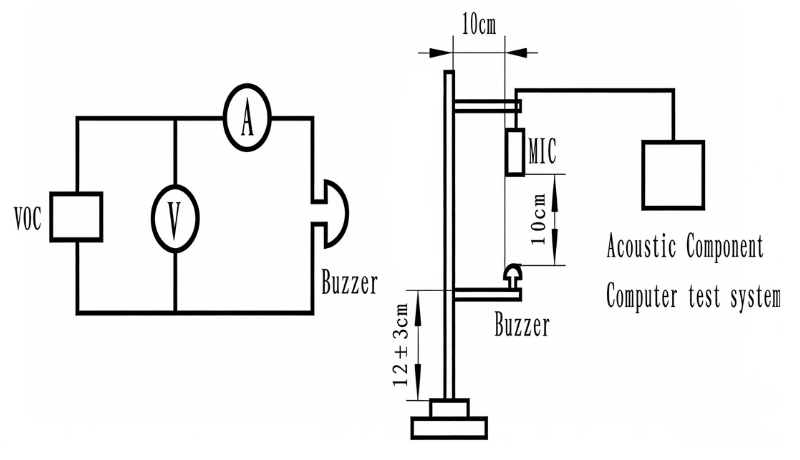

Key performance parameters are verified under controlled standard test conditions to ensure the reliability and consistency required for mass production.

Sound pressure level (≥85dB) is measured at a standard distance of 10cm in a free-field environment. Frequency and current are monitored using the recommended drive circuit.

This buzzer is widely used as a standard alert component in:

We supply this as a standard component for manufacturers worldwide. Support includes:

For datasheets, samples, or to discuss your project’s volume requirements, please contact our sales team.

Our production meets ISO 9001:2015 and ISO 14001:2015 standards and is tailored for automotive applications under the IATF 16949:2016 standard, ensuring comprehensive quality management. Additionally, our products comply with ROHS, CE, and FCC requirements.

Conducting sampling inspections of incoming materials to ensure compliance with standard requirements.

Performing inspection audits to ensure the stability and control of the entire manufacturing process.

Conducting pre-shipment inspections to ensure that products meet established quality standards.

Testing of background noise, sensitivity, frequency response curve, and directionality indicators.

Verification of the impact of different circuits, structural dimensions, materials, and processes on indicators.

Reliability testing at both the new product design stage and the mass production regular stage.

Utilizing fully automated production lines to ensure high efficiency and consistency.

Equipped with state-of-the-art facilities, including a 10,000-level dust-free workshop.

Employing a rigorous 21-step process to guarantee product stability.

5V Active Buzzer for Industrial and Appliance Alarms

5V Active Buzzer for Industrial and Appliance Alarms

Reviews

There are no reviews yet