When observing an electret microphone capsule, the front side typically appears sealed — with no visible holes. That’s because it is usually covered by a dustproof mesh or a waterproof membrane. These layers protect the internal components from dust and moisture while still allowing sound to reach the diaphragm.

Front vs. Rear Holes

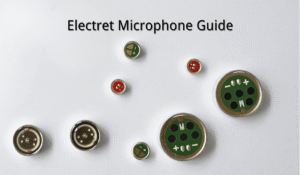

Since the front is visually sealed and acoustically protected, this article focuses on the holes on the rear panel — their number, layout, and acoustic purpose. Rear holes are a key factor in shaping the microphone’s directivity and frequency response. Let’s explore how different microphone types — omnidirectional, bidirectional, and unidirectional — utilize different hole designs to serve their functions.

Omnidirectional Microphones: No or Very Few Rear Holes

Omnidirectional microphone capsules are designed to pick up sound from all directions, but structurally, sound primarily enters from the front. This front opening is usually sealed with a waterproof membrane, which lets sound pass while blocking water ingress.

Because rear holes are not required, the back of the capsule can be completely sealed — making omnidirectional types the only viable choice for IP67-level waterproofing. To learn more about how waterproofing works in microphone design, check out our detailed article: Waterproof vs. Regular Microphones: Design Principles Explained.

Bidirectional Microphones: A Few Rear Holes

Bidirectional microphones capture sound from the front and back while rejecting noise from the sides. This figure-8 pickup pattern is achieved by allowing sound to reach both sides of the diaphragm. Typically, 4 to 6 small acoustic holes are added to the rear panel to enable this function.

At ECMIC, our bidirectional capsules are commonly used in headset microphones and aviation communication headsets, where clear front-and-back pickup is essential while minimizing side interference. Each hole configuration is carefully engineered to balance acoustic performance and structural efficiency.

Unidirectional Microphones: Multiple Rear Holes in Various Patterns

Unidirectional microphones — including cardioid, supercardioid, and hypercardioid — are designed to focus on sound from the front while reducing pickup from the sides and rear. Achieving this requires a more complex rear structure.

These capsules typically feature multiple acoustic holes on the back, working in combination with internal acoustic labyrinths to shape the desired pickup pattern. The hole count and arrangement vary by design. For larger capsules (such as 14mm, 16mm, or 25mm), it’s common to see a dozen or more small vents, particularly in stage or studio applications.

The complexity is not just due to size, but also the directional requirements. These designs are frequently used in conference systems, performance microphones, and KTV or home recording setups, where focused sound pickup and background noise rejection are critical.

Summary

- The front side of electret microphone capsules is sealed with protective mesh or film; this article focuses on rear hole designs.

- Omnidirectional capsules typically have no rear holes, enabling full enclosure for IP67 waterproofing.

- Bidirectional capsules include 4–6 rear holes to allow balanced front and back sound pickup — ideal for headset use.

- Unidirectional capsules feature multiple rear holes that work with internal structures to shape directional sound capture.

Understanding these design strategies helps engineers and manufacturers select the right microphone capsule for their specific applications — balancing acoustics, durability, and environmental resistance. At ECMIC, we offer a wide range of precision-engineered electret microphone elements. Contact us today to discuss your project needs or request a custom microphone capsule design.