Low-frequency impact and vibration detection is increasingly critical in industrial maintenance and infrastructure inspection. Underground cables, pipelines, heavy machinery, and other large-scale equipment require reliable sensing of low-frequency signals to accurately locate faults and ensure operational safety.

Traditional methods often rely on contact sensors or geophones. However, airborne sound sensors, such as electret microphones, can serve as effective auxiliary tools to capture low-frequency acoustic components and improve detection accuracy.

Role of Microphones in Industrial Applications

Electret microphones are small, lightweight, and sensitive, with low inherent noise. While originally designed for audio recording, these microphones can capture low-frequency airborne vibrations, making them suitable as supplementary sensors in industrial monitoring.

When combined with piezo contact sensors or geophones, electret microphones provide a more comprehensive picture of the low-frequency environment. This helps engineers analyze fault locations more efficiently and make informed maintenance decisions.

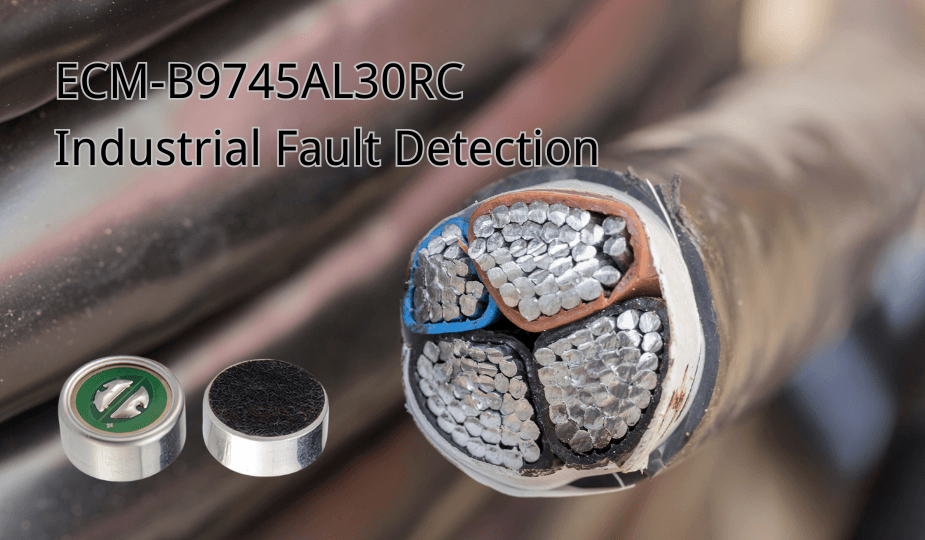

Product Highlight: ECM-B9745AL30RC

The ECM-B9745AL30RC electret microphone offers a compact 9.7 × 4.5 mm form factor, -30 dB ±2 sensitivity, and a frequency response of 50 Hz to 20 kHz. Its signal-to-noise ratio of 74 dB ensures clean signal capture, while the omnidirectional design allows detection from multiple angles.

Key advantages include:

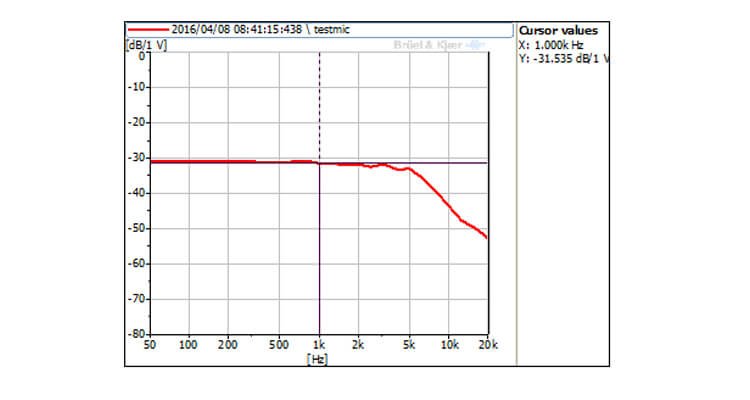

- Flat response in low-frequency range for accurate impact detection

- High-frequency roll-off above 5 kHz to suppress voice and environmental noise

- Compact size for flexible placement in tight industrial setups

- Robust and reliable for various industrial environments

Typical Applications

- Underground cable fault detection: Detect low-frequency acoustic signals generated by surge wave (“thumper”) systems to locate cable faults efficiently.

- Pipelines and industrial machinery: Monitor vibrations or impact sounds from pumps, compressors, and other large equipment.

- Railway and track maintenance: Detect structural vibrations and abnormal low-frequency events for preventive maintenance.

- Deployment strategy: Can be combined with geophones or piezo sensors for hybrid monitoring systems, enhancing overall fault detection accuracy.

ECM-B9745AL30RC Specifications

| Parameter | Value |

|---|---|

| Dimensions | 9.7 × 4.5 mm |

| Sensitivity | -30 dB ± 2 |

| Impedance | 2.2 kΩ |

| Signal-to-Noise Ratio (SNR) | 74 dB |

| Maximum SPL | 110 dB |

| Operating Voltage | 2 Vdc |

| Frequency Response | 50 Hz ~ 20 kHz |

| Directivity | Omnidirectional |

Frequency Response

Example frequency response: flat in the low-frequency range, rolling off above 5 kHz to suppress high-frequency noise and interference.

Although initial inquiries may come from specific regions, the demand for low-frequency fault detection exists globally. Power grids, industrial plants, rail systems, and pipeline networks worldwide can benefit from auxiliary electret microphones to enhance detection capabilities and improve maintenance efficiency.

Electret microphones are valued for their small size, flexibility, and ability to capture acoustic signals in complex environments, complementing traditional contact sensors.

Electret microphones, such as the ECM-B9745AL30RC, are not limited to audio applications. Their low-frequency sensitivity, noise suppression, and compact design make them ideal auxiliary sensors for industrial fault detection and monitoring. By integrating these microphones into hybrid sensing setups, engineers can achieve more accurate and reliable insights into equipment and infrastructure health.

To explore this microphone for your industrial projects, please visit our product page: ECM-B9745AL30RC 9.7mm Omnidirectional Microphone Element.