Micro Dynamic Receiver for Bluetooth Headsets and Hearing Aids

The RE-0633RS-001 is a high-performance micro dynamic receiver designed for clear and reliable audio output. With a compact design and RoHS compliance, this receiver is ideal for various audio applications. It features a copper voice coil, Nd-Fe-B magnet, and a durable ABS frame, ensuring excellent sound quality and long-lasting performance.

For communications device manufacturers

Wholesale & OEM/ODM | 📧 Contact us

🧪 Sample

Standard model free

Shipping cost applies

🧭 Trial Order

From 200 pcs

Test before full order

📦 MOQ

3,000 pcs

Full order minimum

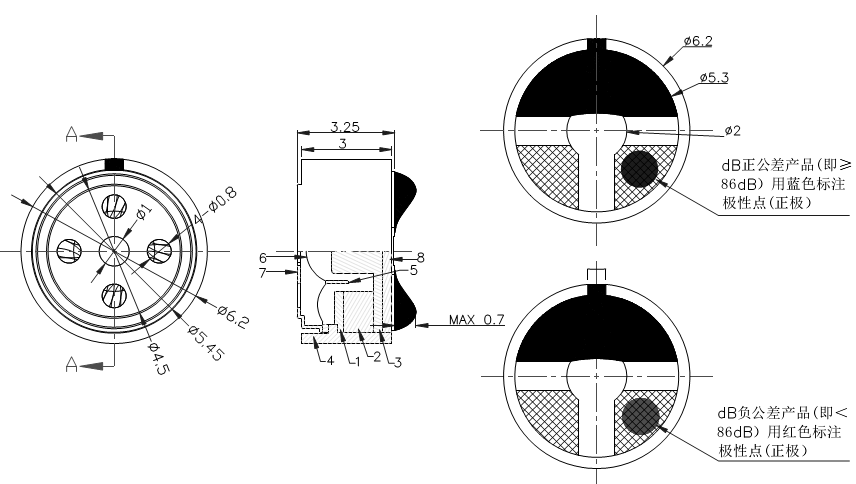

- Model: ECM-RE0633RS-001

- Dimensions: 6.2 × 3.25 mm

- Sensitivity: 86 dB SPL ± 3 dB

- Impedance: 30 Ω ± 20%

- Power: 1 mW

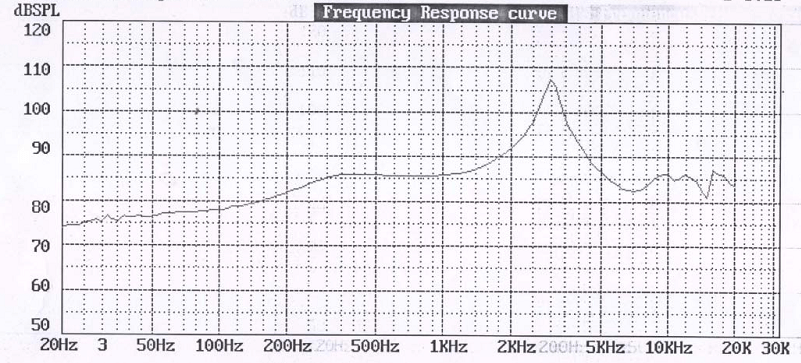

- Frequency Response: 20 Hz ~ 20 kHz

Is this true and does it have any effect on ears that already use hearing aids?

Hi Noel,

Thank you for your question!

While this receiver is not specifically certified or designed for hearing aids, it has been used in similar audio applications. You are welcome to test it in your project, especially if your device allows for some flexibility in receiver specifications.

Please note that for use in regulated medical devices, additional validation and compatibility testing may be required.

Let us know your project requirements or performance targets, and we’ll be happy to assist further.