Récepteur micro-dynamique pour les casques Bluetooth et les aides auditives

Le RE-0633RS-001 est un récepteur micro dynamique de haute performance conçu pour une sortie audio claire et fiable. Avec un design compact et une conformité RoHS, ce récepteur est idéal pour diverses applications audio. Il est doté d'une bobine mobile en cuivre, d'un aimant Nd-Fe-B et d'un cadre ABS durable, garantissant une excellente qualité sonore et des performances durables.

Des quantités minimales de commande (MOQ) s'appliquent.

Pour les fabricants d'appareils de téléphonie et de communication

📞 Contactez nous pour les commandes et les demandes de renseignements.

🧪 Échantillon

Gratuit (modèles standard) + frais de port

🧭 Ordonnance de première instance

A partir de 200 pièces (1ère commande uniquement)

📦 MOQ

3 000 pièces (modèles mixtes autorisés)

- Modèle: ECM-RE0633RS-001

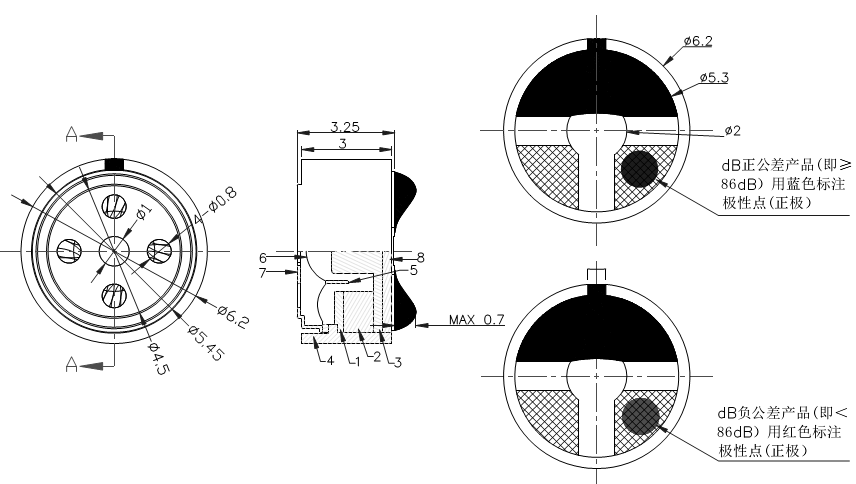

- Dimensions: 6.2 × 3.25 mm

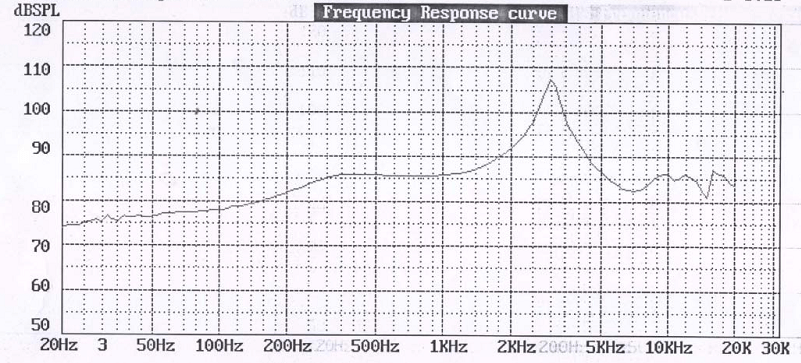

- Sensibilité: 86 dB SPL ± 3 dB

- Impédance: 30 Ω ± 20%

- Puissance : 1 mW

- Fréquence de réponse: 20 Hz ~ 20 kHz

Est-ce vrai et cela a-t-il un effet sur les oreilles qui utilisent déjà des aides auditives ?

Bonjour Noel,

Merci pour votre question !

Bien que ce récepteur ne soit pas spécifiquement certifié ou conçu pour les appareils auditifs, il a été utilisé dans des applications audio similaires. Vous pouvez le tester dans votre projet, surtout si votre appareil permet une certaine flexibilité dans les spécifications du récepteur.

Veuillez noter que pour une utilisation dans des dispositifs médicaux réglementés, des tests de validation et de compatibilité supplémentaires peuvent être nécessaires.

Faites-nous part des exigences de votre projet ou de vos objectifs de performance, et nous serons heureux de vous aider.