Micro-vibration sensors, sometimes referred to as bone-conduction microphones or vibration pickup capsules, are becoming increasingly relevant in product categories that require stable sound capture in challenging conditions. These sensors detect solid-borne mechanical vibration, enabling applications that conventional air-conducted microphones cannot reliably support.

One commonly used model in vibration pickup applications is the ECM-B9745AL70-318A (9.7 mm vibration microphone capsule), which provides compact size and high sensitivity for close-contact sensing.

Key Features and Specifications

| Parameter | Value |

|---|---|

| Dimensions | 9.7 × 4.5 mm |

| Directivity | Omnidirectional |

| Sensitivity | −70 dB ± 3 |

| Impedance | 2.2 kΩ |

| S/N Ratio | 40 dB |

| Max SPL | 125 dB |

| Operating Voltage | 4.5 Vdc |

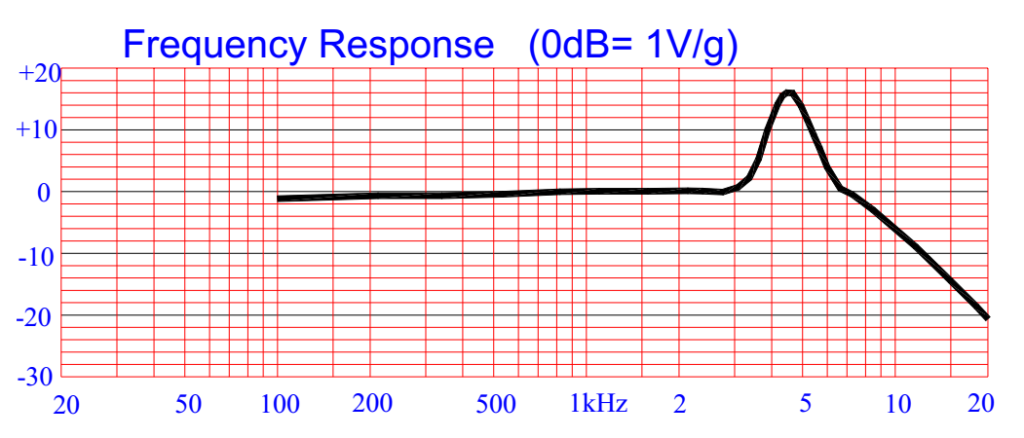

| Frequency Response | 100 Hz – 20 kHz (effective vibration band approx. 100 Hz – 7 kHz) |

Where Micro-Vibration Sensors Are Being Used

Because micro-vibration sensors respond to mechanical surface vibration rather than airborne sound waves, they offer high stability in environments where traditional microphones struggle.

1. Throat Microphones and Voice Pickup Under Noise

Micro-vibration sensors are widely used in throat microphone systems that require:

- stable speech capture under high environmental noise

- voice pickup when airborne sound is weak or obstructed

- applications where privacy or quiet speaking is needed

2. Digital Stethoscopes and Medical Monitoring

In medical and veterinary devices, vibration sensors help detect:

- heart and lung vibration signatures

- biometric micro-movement patterns

- contact-based diagnostic acoustics

3. Musical Instrument Contact Pickups

Micro-vibration capsules are also used in:

- Cajon and wooden percussion pickups

- acoustic instrument amplification

- noise-free stage monitoring systems

Their wide effective bandwidth allows for natural vibration-based tone capture without environmental interference.

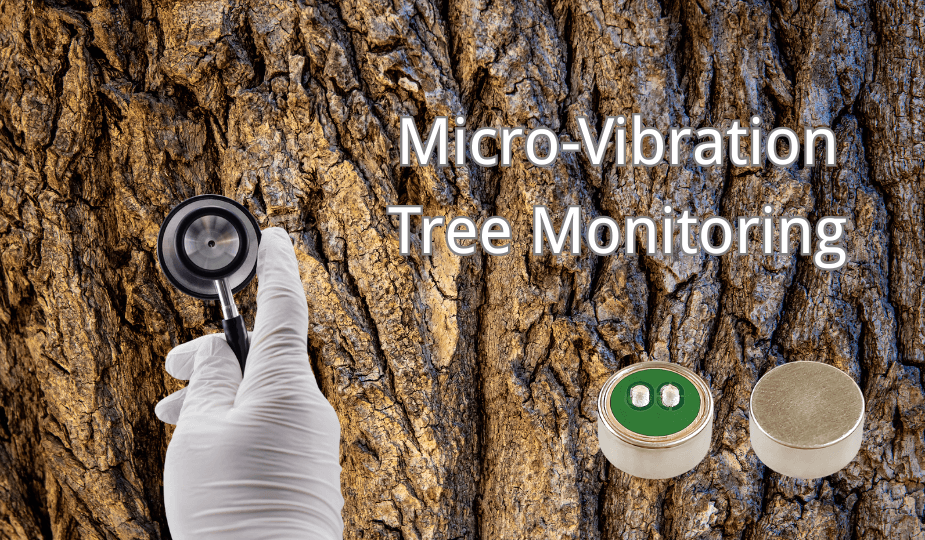

4. Forestry, Agriculture, and Research Monitoring

One unique application is detecting insects chewing inside wood. Micro-vibration sensors can reveal:

- internal activity inside tree trunks

- early pest infestation signs

- structural changes in wooden or organic materials

Researchers and environmental agencies use these sensors as non-destructive inspection tools.

Suitable for OEM and ODM Development

For small and medium-sized manufacturers, micro-vibration sensors offer:

- easy integration with analog circuits

- cost-effective production scaling

- stable sourcing without custom ASIC requirements

- adaptability for multiple categories

This makes them a practical choice for communication products, medical startups, musical instrument brands, and sensing technology developers.

Micro-vibration sensing technology is becoming increasingly valuable across communication, medical diagnostics, acoustic instruments, and environmental monitoring. The ECM-B9745AL70-318A provides a compact and reliable solution for close-contact pickup applications, making it a strong candidate for future OEM/ODM projects where vibration sensing plays a key role.