Why Choose Our Products?

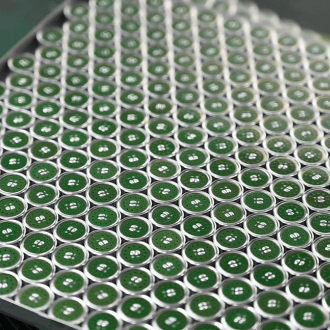

Tight Sealing

Advanced automated sealing technology ensures each microphone component is tightly sealed, effectively preventing external noise interference and enhancing product stability and reliability.

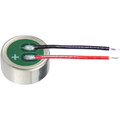

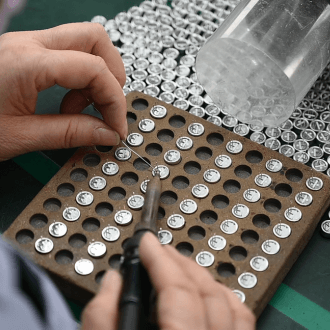

Secure Soldering

Precision soldering techniques ensure each solder joint is secure, reducing the risk of poor contact and disconnection, guaranteeing long-term stable operation.

Multi-Interface Support

Our production line supports traditional pin soldering and can also provide solder joint and wire interfaces based on customer requirements, adapting to different design needs.